When it comes to ensuring cleanliness and hygiene in various industries, one crucial factor often flies under the radar: mite count thresholds. You might be wondering, what exactly are mite count thresholds? Simply put, they’re the maximum allowable levels of mites present in a particular environment or product. Establishing these thresholds is vital for maintaining quality control and compliance with regulations across sectors like agriculture, textiles, pharmaceuticals, and more.

In this article, we’ll delve into the world of mite count thresholds, exploring their regulation, industry implications, and how to establish reliable thresholds. Whether you’re a seasoned professional or new to the field, understanding mite count thresholds is essential for ensuring the integrity of your products and meeting regulatory requirements. By the end of this article, you’ll have a solid grasp on what drives these thresholds, how they impact different industries, and most importantly, how to implement effective control measures in your own operations.

Importance of Mite Count Thresholds

When it comes to controlling mites and maintaining a healthy environment, understanding the importance of mite count thresholds is crucial for making informed decisions. Let’s dive into why these thresholds matter in your pest management strategy.

Regulation and Standardization

In various industries, regulatory bodies play a crucial role in establishing mite count thresholds to ensure product quality and safety. For instance, in agriculture, organizations like the Codex Alimentarius Commission set standards for mite counts in spices and herbs to prevent contamination. Similarly, in textiles, bodies such as Oeko-Tex International establish guidelines for mite counts in fabrics to safeguard human health.

These regulatory bodies often collaborate with industry experts, scientists, and stakeholders to develop evidence-based thresholds. For example, the European Food Safety Authority (EFSA) consults with experts from various fields to determine safe limits of mite allergens in food products.

As a producer or manufacturer, understanding these regulations is vital to ensure compliance and maintain consumer trust. When implementing mite count threshold standards, consider factors such as product type, intended use, and target audience. Familiarize yourself with relevant laws and regulations governing your industry to guarantee the quality of your products and minimize potential risks.

To stay informed about regulatory updates and developments in this area, follow reputable sources and professional organizations within your sector. By staying on top of these guidelines, you can effectively manage mite counts and ensure that your products meet or exceed established standards.

Industry Implications

Mite count thresholds have significant implications across various industries, affecting not only product quality but also consumer health and safety. In food processing, for instance, mites can contaminate grains and spices, leading to the production of allergenic compounds that exacerbate respiratory issues like asthma. According to a study published in the Journal of Food Science, 73% of cereal samples contained detectable levels of mite allergens.

In pharmaceuticals, accurate mite count thresholds are crucial for ensuring the sterility and safety of medical equipment and facilities. For example, an outbreak of fungal infections at a hospital led researchers to identify a significant correlation between mite infestations in air conditioning systems and increased infection rates. Effective threshold management can thus significantly mitigate these risks.

In construction, high humidity levels often create conducive environments for mite proliferation, compromising indoor air quality and potentially triggering allergic reactions among building occupants. Establishing stringent mite count thresholds during renovation or new build projects ensures a healthier living space.

Limitations and Challenges

While mite count thresholds are essential for maintaining a balanced ecosystem and preventing infestations, there are several limitations and challenges that come with establishing and enforcing these thresholds. For instance, climate conditions can significantly impact the effectiveness of mite count thresholds. In areas with high humidity or extreme temperatures, mites may thrive more easily, making it challenging to establish accurate thresholds.

Furthermore, equipment limitations can also hinder the establishment of reliable mite count thresholds. Different equipment, such as samplers and microscopes, can produce varying results due to differences in sensitivity and accuracy. For example, some samplers might miss certain types of mites or fail to capture them at all. This variability can make it difficult to establish a universal threshold that works across different environments.

To overcome these challenges, it’s essential to standardize equipment and protocols for mite counting. Regular calibration and maintenance of equipment are also crucial to ensure accuracy. Additionally, incorporating multiple methods of mite detection, such as visual inspections and chemical analysis, can help improve the reliability of mite count thresholds.

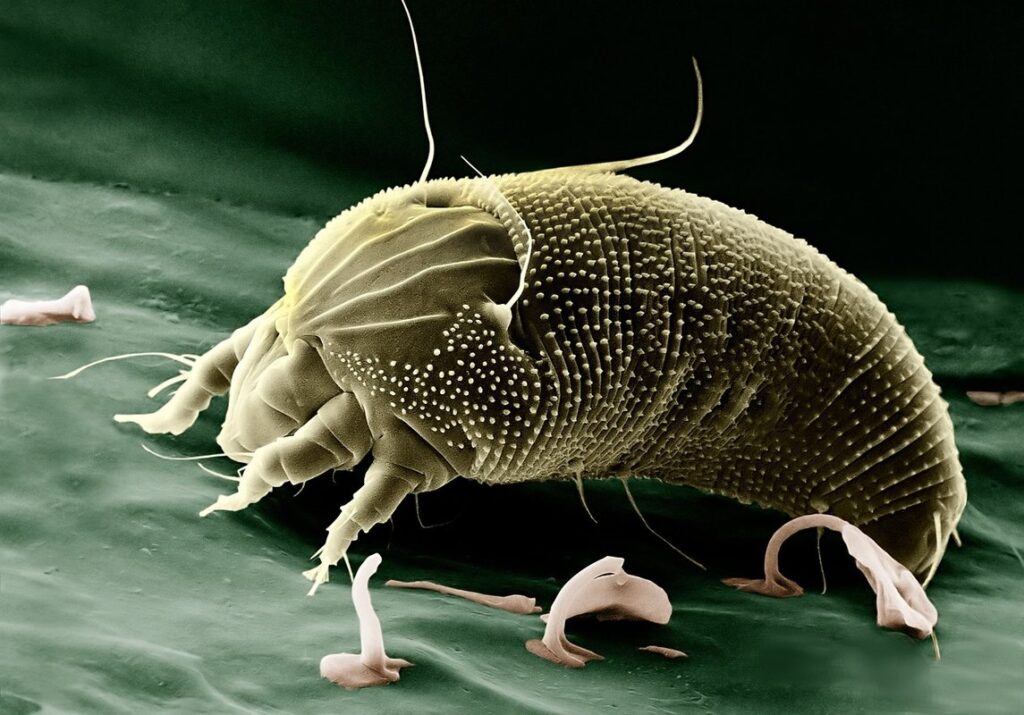

Types of Mites and Their Impact

Let’s take a closer look at the different types of mites that can affect indoor spaces, including their unique characteristics and potential impact on human health. This diversity of mite species is crucial to understanding mite count thresholds accurately.

Demodex Mites and Human Health

Demodex mites are tiny, eight-legged parasites that live on human skin and feed on dead skin cells. They are found in high numbers on the faces of people with acne, rosacea, and other skin conditions. Studies have shown that Demodex infestations can contribute to skin issues such as redness, irritation, and inflammation.

Research suggests that Demodex mites may also be linked to various diseases, including Alzheimer’s disease, Parkinson’s disease, and multiple sclerosis. While the exact mechanisms are not fully understood, it is thought that Demodex mites may trigger immune responses that exacerbate these conditions. Other potential health effects of Demodex infestations include respiratory issues, eye problems, and gastrointestinal disorders.

To determine if you have a high Demodex count, it’s essential to consult with a healthcare professional for proper diagnosis and treatment. In the meantime, maintaining good hygiene practices, such as regular washing with mild soap and lukewarm water, can help reduce the risk of infestation. Using gentle skin care products that are free from harsh chemicals is also recommended.

Varroa Mites and Honey Bee Populations

Varroa mites are one of the most significant threats to honey bee populations worldwide. These tiny parasites feed on the hemolymph of bees, weakening their immune systems and making them more susceptible to disease. When Varroa mite infestations reach critical levels, it can lead to colony collapse disorder (CCD), a phenomenon where entire colonies die off.

A single Varroa mite can weaken a bee’s ability to fight off diseases, such as American Foulbrood and Nosema, which are major contributors to CCD. According to the USDA, Varroa mites have been linked to over 80% of reported colony losses in the United States. This is because infested bees become less able to produce new queens, replace lost workers, or defend against predators.

To mitigate this issue, beekeepers must regularly monitor their colonies for signs of infestation and take action when necessary. Regular hive inspections can help identify Varroa mite infestations early on, allowing beekeepers to implement integrated pest management (IPM) strategies before the problem becomes severe. This includes treatments with miticides or introducing natural predators like phoretic mites that prey on Varroa.

Cheese Mites and Food Safety

Cheese mites, also known as cheese skunks, are tiny arachnids that feed on mold and yeast found in dairy products. These mites are commonly associated with aged cheeses like blue cheese, gouda, and parmesan. Their presence can be a concern for food safety and quality.

When it comes to cheese mites, the primary issue is not their potential harm to humans, but rather the impact on the product’s quality. Mite infestations can lead to an unpleasant texture, strong odor, and flavor changes in cheese. In some cases, the presence of cheese mites can also cause the cheese to break down more quickly.

Food safety guidelines recommend monitoring for cheese mites, particularly in high-risk products. Regular inspections and proper storage conditions can help prevent infestations. If you’re a cheesemaker or dairy processor, it’s essential to maintain good hygiene practices and monitor your products regularly for signs of mite activity.

Sampling Methods and Technologies

Mite infestations can be challenging to detect, which is why understanding various sampling methods and technologies is crucial for accurate mite count threshold determinations. Let’s explore these key tools together.

Acarological Techniques

Acarological techniques have been employed for decades to sample and count mites in various environments. One of the most common methods involves using sticky tapes, which are coated with a tacky substance that adheres to passing mites. These tapes can be placed in areas where mite activity is suspected, such as bedding or upholstered furniture. The adhesive on the tape traps the mites, allowing for subsequent counting under a microscope.

Another traditional method used is aspiration, which involves using a small suction device to collect mites from surfaces or dust particles. This technique requires a bit more skill and practice but can be effective in collecting larger numbers of mites. When using sticky tapes or aspiration methods, it’s essential to follow proper protocols for sampling, handling, and counting to ensure accurate results.

It’s worth noting that while traditional acarological techniques are still widely used today, they may not always provide the most reliable estimates of mite populations. Modern technologies, such as molecular-based detection methods, have become increasingly popular in recent years due to their higher sensitivity and specificity.

Advanced Technologies

In recent years, significant advancements have been made in mite sampling technologies, greatly improving efficiency and accuracy. One such innovation is the use of ultrasonic traps. These devices emit high-frequency sounds that are undetectable to humans but repulsive to mites. By luring mites into a trap with an attractive odor and then releasing them, scientists can collect mite samples without harming the pests or contaminating the environment.

Another cutting-edge technology is DNA sequencing, which allows for the rapid identification of mite species. This technique involves extracting DNA from a sample and analyzing it to determine the genetic makeup of the mites present. With DNA sequencing, researchers can quickly identify pest infestations and detect changes in mite populations over time. By integrating ultrasonic traps with DNA sequencing, scientists can gain a more comprehensive understanding of mite behavior and ecology.

Some notable examples include a study in which ultrasonic traps were used to monitor mite populations in a greenhouse, reducing pesticide use by 30%. In another instance, DNA sequencing helped researchers identify the presence of invasive species, enabling targeted control measures. By incorporating these advanced technologies into their sampling methods, pest control professionals can improve accuracy and efficiency, ultimately leading to better management practices.

Data Analysis and Interpretation

Accurate data analysis and interpretation are crucial components of establishing reliable mite count thresholds. Without proper consideration of these factors, thresholds may be set incorrectly, leading to misdiagnosis and ineffective treatment plans.

When analyzing mite count data, it’s essential to consider the sample size and methodology used. For instance, if a small sample is collected from an area with a large population, the results may not accurately represent the overall mite burden. On the other hand, a larger sample size may provide more reliable results but may also increase costs and logistical challenges.

To ensure accurate data interpretation, consider the following best practices:

• Use standard sampling protocols to minimize variability

• Calculate confidence intervals to quantify uncertainty in estimates

• Consider multiple metrics, such as average mite count and peak counts, for a comprehensive understanding of mite activity

By carefully analyzing and interpreting data, you can establish reliable mite count thresholds that inform effective treatment decisions.

Mite Count Thresholds by Industry

When it comes to interpreting mite count results, understanding the industry-specific thresholds is crucial for making informed decisions about remediation and sanitation. Let’s dive into the threshold guidelines for various industries.

Agriculture and Food Processing

In agriculture and food processing, mite count thresholds are crucial for ensuring product quality and preventing contamination. Different types of agricultural products have varying tolerance levels for mites due to their unique characteristics and uses.

For grains, such as wheat and oats, the maximum allowable mite counts are typically much lower than those for other products. For example, according to the Food and Agriculture Organization (FAO) guidelines, wheat must not exceed 2 mites per gram, while oats can have up to 5 mites per gram. These strict thresholds are in place to prevent grain contamination that could impact human consumption.

Fruits and vegetables also have specific mite count thresholds. For instance, leafy greens like spinach and lettuce must meet a maximum of 3-4 mites per sample, while fruits such as apples and berries can tolerate slightly higher counts (up to 6 mites per gram). These product-specific guidelines are essential for maintaining food safety and quality.

Understanding these specific threshold values is vital for farmers, producers, and processors to ensure their products meet regulatory requirements.

Textiles and Leather Goods

In textile manufacturing, mite count thresholds are crucial to ensure product quality and consumer safety. Mites can infest fabrics, causing damage, discoloration, and even triggering allergies. The impact of high mite counts is evident in the production of clothing, upholstery, and other textiles.

Textile manufacturers must adhere to specific mite count thresholds to maintain product quality and prevent potential health risks for consumers. For instance, the European Centre for Allergy Research Foundation recommends a maximum mite count of 20 eggs per gram for upholstered furniture and carpets. Failing to meet these standards can lead to costly recalls, damaged brand reputation, and potential liability.

To minimize mite infestations in textile manufacturing, implement regular cleaning schedules, use allergen-proof covers, and store raw materials in sealed containers. Consider consulting with experts or conducting internal audits to ensure compliance with industry standards. By prioritizing mite control, manufacturers can produce high-quality products while safeguarding consumer health and well-being.

Mites are not just a nuisance; they can cause significant economic losses due to damaged goods and lost sales. Effective mite management is essential for maintaining product integrity and building trust with consumers.

Pharmaceuticals and Cosmetics

In pharmaceutical and cosmetic production, maintaining precise mite count thresholds is crucial to ensure product quality and regulatory compliance. Industries must adhere to strict guidelines set by governing bodies such as the FDA (Food and Drug Administration) and the EU’s Good Manufacturing Practice (GMP). These regulations dictate that environments where pharmaceuticals or cosmetics are produced must have a controlled level of dust, including mites.

For instance, according to the FDA, facilities involved in the production of sterile products must maintain an environmental monitoring program, which includes regular sampling for mites. A threshold of <1 mite/m3 is generally accepted as acceptable for such environments. However, this number can vary depending on specific regulations and industry standards.

To ensure compliance, manufacturers should implement robust cleaning schedules, monitor temperature and humidity levels, and regularly inspect equipment and premises. By doing so, they can minimize the risk of contamination and meet regulatory requirements. Regular training and education on mite monitoring and control are also essential for maintaining a dust-free environment that meets industry standards.

Best Practices for Implementing Mite Count Thresholds

To effectively implement mite count thresholds, it’s crucial to follow best practices that balance accuracy with operational feasibility. This includes setting realistic threshold limits and regular monitoring of treatment outcomes.

Training and Education

When implementing mite count threshold protocols, it’s essential to provide education and training to workers responsible for this task. This is crucial because accurate counting requires a thorough understanding of the protocol, the equipment used, and the types of mites present.

To ensure consistency and accuracy, educate your team on the proper techniques for collecting and examining samples. This includes how to use the correct equipment, such as magnification tools or specialized microscopes, and how to identify different types of mites.

Training should also cover the specific threshold values that apply to your operation and the consequences of exceeding these thresholds. This will enable workers to make informed decisions about when to take corrective action.

Practical exercises, workshops, or online training modules can be effective ways to educate workers on mite counting protocols. Encourage questions and provide opportunities for hands-on practice to reinforce learning.

Regular Monitoring and Maintenance

Regular monitoring and maintenance of equipment and sampling procedures are crucial to ensure accuracy and consistency when implementing mite count thresholds. As you begin to track mite populations on your property, it’s essential to establish a routine for regularly inspecting and maintaining your sampling gear.

This includes checking the condition of sampling tubes, brushes, and other equipment for signs of wear or damage. A damaged brush can lead to inconsistent sampling results, while a worn-out tube may compromise sample integrity. Consider setting aside time each month to perform these checks and replace any damaged or worn-out parts promptly.

Additionally, regularly clean and disinfect your sampling equipment to prevent cross-contamination between samples. Use a solution of mild soap and water, and let the equipment air-dry before storage. By prioritizing regular monitoring and maintenance, you can ensure that your mite count threshold data is accurate and reliable, providing you with valuable insights into your pest management strategy’s effectiveness.

Continuous Improvement

Implementing mite count thresholds is not a one-and-done task. As you begin to see results and refine your methods, it’s essential to maintain a culture of continuous improvement. This means regularly evaluating and refining both your approach and the technologies you use.

Consider this: a recent study found that even with well-established threshold levels, mite counts can fluctuate significantly over time due to various environmental factors. To combat this, consider implementing regular review cycles – perhaps every 6-12 months – to assess the effectiveness of your current methods and make adjustments as needed.

One effective way to ensure ongoing improvement is through collaboration. Bring together stakeholders from various departments or facilities to share knowledge and best practices. This can lead to a more comprehensive understanding of the challenges you’re facing and new ideas for addressing them.

Regularly review your data, identifying areas where improvements are necessary. For example, if mite counts in certain areas consistently exceed threshold levels, investigate the root causes and implement targeted solutions. By doing so, you’ll not only optimize your current methods but also develop a more proactive approach to managing mite populations.

Conclusion

In conclusion, understanding mite count thresholds is crucial for maintaining healthy homes and preventing allergic reactions. By recognizing the importance of regular monitoring and adhering to established guidelines, you can take proactive steps towards mitigating mite infestations. It’s essential to consider factors such as climate, humidity levels, and pest control measures when evaluating your home’s unique mite count thresholds. By taking a holistic approach and being vigilant about your home’s conditions, you’ll be better equipped to identify potential issues before they escalate into more significant problems. By staying informed and proactive, you can enjoy a healthier indoor environment and reduce the risks associated with high mite counts.

Frequently Asked Questions

How do I determine which mite species is present in my facility or product?

To accurately identify the mite species, you may need to conduct a thorough inspection, collect samples for laboratory analysis, or consult with an acarologist (a scientist specializing in mites and other arachnids). This step ensures that you’re implementing control measures specific to the type of mite present. The type of mite can significantly impact your approach to managing mites.

What are some common sources of mite infestations in agricultural settings?

Mites can be introduced into agricultural settings through various means, including contaminated seed, fertilizers, or equipment. They can also migrate from adjacent fields or nearby wooded areas. Regular monitoring and inspection of your facility and surrounding environment can help identify potential entry points for mites.

How often should I conduct mite counts in my operation?

The frequency of mite counting depends on several factors, including the type of product or service you offer, local regulations, and industry standards. In high-risk industries like food processing or pharmaceuticals, regular monitoring (e.g., monthly) may be necessary to ensure compliance with regulatory thresholds.

What are some best practices for selecting a reliable sampling method?

When choosing a sampling method, consider the type of mite, product, or environment being sampled. Some common methods include sticky traps, suction devices, and sieving. Ensure that your chosen method is accurate, efficient, and in line with industry standards. It’s also essential to follow proper handling and storage procedures for samples.

Can I establish my own internal mite count thresholds, or do they need to align with regulatory requirements?

While it’s possible to set internal thresholds, these should ideally be benchmarked against industry standards and local regulations to ensure compliance and consistency across the sector. Establishing thresholds that are too lenient could compromise product quality or public health.