As the temperatures drop and winter sets in, beekeepers know that protecting their precious colonies is crucial. A well-insulated beehive can mean the difference between life and death for your bees during this harsh season. But insulating a beehive isn’t just about keeping them warm – it’s also about boosting honey production and overall hive health. If you’re new to beekeeping or struggling with winter losses, you’ve come to the right place. In this article, we’ll delve into the world of effective insulation for beehives during winter. We’ll explore both natural materials like straw and shredded newspaper, as well as commercial products that can help keep your bees safe and thriving. From real-world success stories to practical tips and tricks, you’ll learn everything you need to know to keep your hive healthy and happy all winter long.

Understanding the Importance of Insulation in Beehives

When it comes to keeping your beehive warm and cozy during the cold winter months, insulation is more than just a nice-to-have – it’s crucial for your bees’ survival. Let’s explore why proper insulation matters in the first place.

The Role of Temperature in Beehive Health

Temperature plays a crucial role in maintaining the health and well-being of bees within their beehive. A stable temperature is essential for proper brood development, honey production, and bee behavior. Bees maintain a consistent temperature between 92°F to 95°F (33°C to 35°C) inside the hive through cluster formation, where they surround the queen and brood to keep them warm.

A temperature drop below this range can be detrimental to the colony’s health. Brood development slows down, leading to reduced honey production and potentially even death of the brood. Similarly, an increase in temperature above 95°F (35°C) can lead to stress on the bees, causing them to become lethargic and reducing their ability to perform essential tasks.

Insulation is key to maintaining a stable temperature within the beehive during winter months. By keeping cold air out and retaining warmth, insulation helps maintain an optimal temperature range for brood development, honey production, and bee behavior. When selecting insulation materials, consider using natural materials like straw bales or wool, which are breathable and can help regulate temperature fluctuations.

Common Issues with Cold Bees

When it comes to keeping our bee friends cozy during the harsh winter months, insulation is key. However, there are some common issues that can arise when cold beehives aren’t properly insulated. One of the most critical problems is cluster failure, where the bees’ clustered temperature drops below a certain threshold, making it difficult for them to survive.

This usually happens when the hive’s heat source, provided by the worker bees fanning their wings and generating heat through metabolism, isn’t sufficient due to inadequate insulation. As a result, the queen may not be able to lay eggs, leading to reduced honey stores. In extreme cases, this can even lead to queen loss.

To avoid these issues, it’s essential to ensure your hive is well-insulated. This means using materials like wood or foam to line the hive walls and floor, as well as adding insulation around the hive entrance to prevent cold air from entering. By taking proactive steps to keep your beehive warm and cozy, you can help your bees thrive even in the coldest of winters.

Some beekeepers use a technique called “cluster management” to mitigate this issue. This involves manipulating the cluster’s position within the hive to maximize its surface area and ensure that it has enough space to generate heat. By monitoring temperature fluctuations and adjusting the cluster’s position accordingly, you can help prevent cluster failure and keep your bees safe and healthy during the winter months.

Types of Insulation for Beehives

When it comes to insulating your beehive, you have several options to choose from, including foam board insulation and straw bales. We’ll explore these alternatives in more detail below.

Natural Materials: Straw, Shavings, and Hay

When it comes to insulating beehives with natural materials, straw, shavings, and hay are popular choices. These organic materials are readily available, biodegradable, and can provide excellent insulation properties.

Straw is a good option for insulating beehives, especially in areas where it’s readily available as a crop waste product. It provides good thermal mass, meaning it can absorb and release heat slowly, helping to regulate the temperature inside the hive. However, straw can be prone to mold and moisture issues if not properly maintained.

Wood shavings are another natural material used for insulation. They’re lightweight, easy to install, and can provide decent insulation properties. However, they may not be as effective in extremely cold temperatures or high winds. It’s essential to ensure the shavings are dry and free of debris before using them.

Hay is also sometimes used for insulating beehives, particularly in emergency situations where other materials aren’t available. While it provides some insulation, hay can be a fire hazard if not properly secured, and may harbor pests like rodents or insects.

When using natural materials like straw, shavings, or hay, it’s crucial to ensure they’re dry, clean, and free of debris before installing them in the hive. This will help prevent moisture issues, mold growth, and pest infestations. Additionally, regular maintenance is key to extending the lifespan of these natural insulation materials.

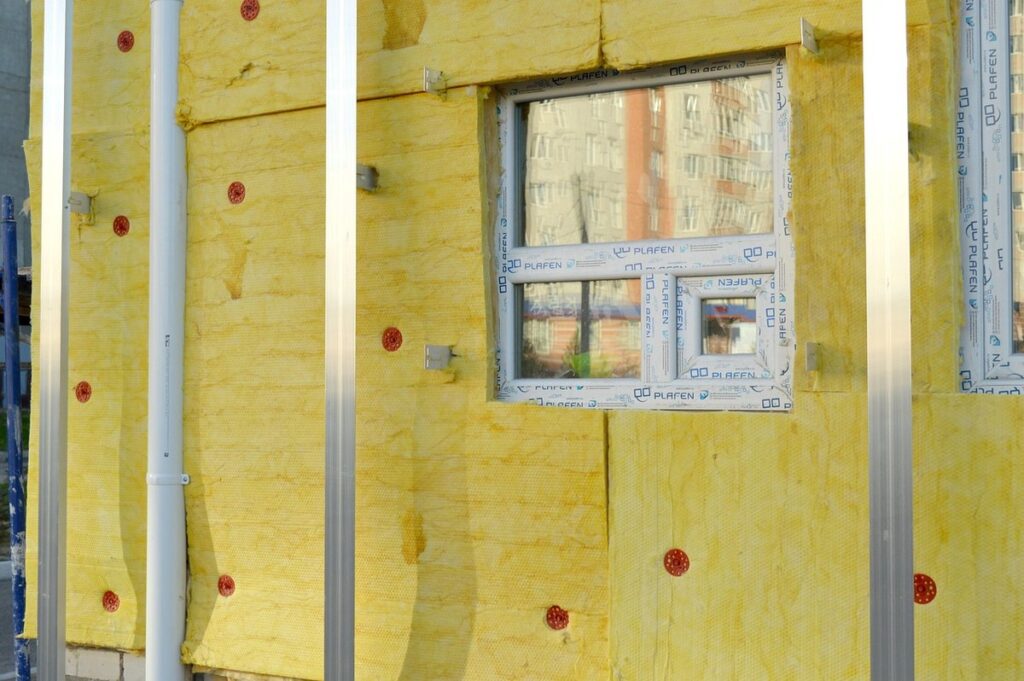

Synthetic Options: Foam Boards and Plastic Sheets

When it comes to synthetic insulation options, foam boards and plastic sheets are two popular choices for beehives. These materials provide a cost-effective solution while offering good thermal resistance.

Foam boards, typically made from polyisocyanurate (PIR) or polyurethane (PUR), offer high R-values in thin profiles, making them an attractive option for insulation. However, they can also release chemicals during the manufacturing process, which may affect the health of the bees. It’s essential to choose foam boards with low VOCs (volatile organic compounds).

Plastic sheets, on the other hand, are made from durable materials like HDPE or LDPE and provide a waterproof barrier against moisture. They are easy to install and maintain but may not offer the same level of thermal resistance as foam boards.

Consider using foam boards for beehives that are exposed to harsh weather conditions, while plastic sheets can work well in dry environments with minimal temperature fluctuations. Always follow the manufacturer’s instructions for installation and ensure proper ventilation to prevent moisture buildup.

DIY Insulation Methods for Beehives

When it comes to insulating your beehive for winter, you’ll want to explore cost-effective and eco-friendly methods that don’t compromise on performance. Let’s dive into some practical DIY insulation ideas.

Using Local Materials to Create a Natural Insulator

When it comes to insulating your beehive for winter, repurposing local materials is not only eco-friendly but also cost-effective. One creative way to create a natural insulator is by using recycled denim jeans. Yes, you read that right – denim! Denim insulation is gaining popularity among beekeepers due to its thermal performance and sustainability.

To make denim insulation, simply cut the denim into strips or squares, depending on your beehive’s design. You can then layer these pieces within the hive, leaving about 1-2 inches of space between each layer for airflow. This will help regulate temperature and humidity levels inside the hive. Another option is to use cardboard boxes, which can be cut to fit snugly into the hive. Simply wrap the cardboard in a breathable material like muslin or cotton cloth to prevent moisture buildup.

These creative solutions not only reduce waste but also provide excellent insulation for your beehive. By using local materials, you’re promoting sustainability and reducing your carbon footprint while keeping your bees cozy during winter. Remember to always choose materials that are dry, clean, and free of pesticides to ensure the health and safety of your colony.

Simple Assembly Techniques for Foam Board Installation

When assembling foam board insulation for beehives, it’s essential to follow simple and effective techniques to ensure a secure fit. Begin by cutting the foam board to size using a utility knife or a saw, taking care to maintain precise measurements to fit snugly around the hive.

Next, peel off the protective film from both sides of the foam board, as this will help prevent any damage during installation. To assemble the insulation pieces, start by placing the first piece against the hive’s exterior, ensuring it is centered and secure. Use a staple gun or nails to attach the foam board to the hive’s frame, making sure not to compromise its structural integrity.

For corners, use a 45-degree angle to cut two adjacent pieces of foam board and fit them together seamlessly. This will create a tight seal and prevent any gaps where cold air can penetrate. It’s also crucial to leave about an inch of space between the insulation and the hive’s entrance to facilitate ventilation.

Commercial Insulation Products for Beehives

When choosing commercial insulation products for beehives, it’s essential to consider factors such as durability, moisture resistance, and ease of installation. We’ll explore top-rated options for beekeepers in this section.

Product Review: Top-Rated Insulation Kits and Materials

When it comes to choosing the right insulation kit and materials for your beehive, there are several top-rated options available on the market. One popular choice is the Beehive Insulation Kit by Mann Lake, which includes a combination of foam board insulation and a breathable membrane. This kit provides excellent temperature regulation and moisture protection, helping to keep your bees safe and healthy throughout the winter months.

Another highly-recommended option is the 3M Thinsulate Insulation, which offers superior thermal performance and ease of installation. Its flexible design allows for seamless integration with various beehive styles and sizes. Additionally, the product’s unique fibers provide excellent moisture-wicking properties, helping to prevent ice dams from forming on your beehive.

In terms of DIY insulation materials, many beekeepers swear by the effectiveness of straw or excelsior packing. These natural, breathable materials are inexpensive and easy to source locally. However, they may require more frequent maintenance than synthetic insulation products. When selecting an insulation kit or material, consider factors such as temperature extremes, humidity levels, and your local climate to ensure you choose a product that meets your beehive’s specific needs.

Comparing Different Brands and Price Points

When shopping for commercial insulation products for your beehives, it’s essential to compare different brands and price points. This will help you make an informed decision that suits your budget and meets the specific needs of your bees.

Some popular brands on the market include foam insulation like Foamex and Thermax, which are known for their high-quality and durability. However, these premium options come with a higher price tag, typically ranging from $100 to $300 per sheet. On the other hand, you have more affordable options like Reflectix, which offer excellent value for money, priced between $20 to $50 per roll.

Another key factor to consider is the R-value, or thermal resistance, of the insulation product. A higher R-value indicates better performance in colder temperatures. For instance, a product with an R-value of 4-5 may be suitable for milder climates, while those living in areas with harsh winters will need something with a higher R-value (e.g., R-8 or R-10).

Ultimately, the best insulation brand and price point for you will depend on your specific needs, climate, and budget. Consider consulting with local beekeepers, suppliers, or experts to get personalized advice and ensure you choose the most suitable insulation product for your beehives.

Maintenance and Upkeep: Ensuring Effective Insulation

To keep your beehive insulated all winter, you’ll need to regularly inspect and maintain its thermal envelope, checking for gaps and damage. Regular upkeep is crucial to prevent costly repairs.

Monitoring Temperature Fluctuations and Adjustments

Monitoring temperature fluctuations is crucial to maintain a healthy beehive during winter. To do this effectively, you’ll need to invest in a thermometer specifically designed for beehives. These thermometers can be installed inside the hive and will provide accurate readings of the internal temperature.

Regularly check the temperature readings throughout the day to identify any unusual fluctuations. Bees maintain their optimal body temperature around 92-95°F (33-35°C). If the temperature drops below this range, it may cause issues with brood development and overall health. Conversely, temperatures above 100°F (38°C) can lead to excessive moisture buildup within the hive.

Adjustments should be made based on these readings. For instance, if the temperature inside the hive is consistently lower than ideal, additional insulation might be necessary. This could involve adding more material around the edges of the hive or increasing the thickness of existing insulation. Conversely, if temperatures are too high, some insulation may need to be removed to allow for better airflow and moisture dissipation.

Regular Cleaning and Inspection Schedules

Regular cleaning and inspection of beehive insulation is crucial to ensure its effectiveness during winter. As the cold weather sets in, excess moisture and debris can compromise the integrity of your insulation, leading to heat loss and potential damage to your bees.

Schedule regular cleaning sessions every 2-3 weeks during the winter months. Begin by removing any visible debris, such as dead bees or hive debris, using a soft-bristled brush or a vacuum cleaner with a gentle suction setting. Next, inspect the insulation for signs of wear, moisture buildup, or pest infestation.

Check for any gaps or holes in the insulation that may allow cold air to seep in. Use caulk or foam sealant to fill any cracks and ensure a tight seal. Don’t forget to inspect the hive’s ventilation system to ensure proper airflow and moisture removal.

Remember, regular cleaning and inspection will help maintain your beehive’s energy efficiency and keep your bees safe and healthy throughout the winter season. By following this simple schedule, you’ll be able to monitor any potential issues early on and take corrective action before they become major problems.

Seasonal Considerations: Preparing Your Beehive for Winter

As winter approaches, it’s essential to think ahead and prepare your beehive for the cold months by considering factors like temperature fluctuations and potential pest infestations. Let’s dive into how these considerations can inform your insulation choices.

Early Fall Preparation and Insulation Installation

As we transition into early fall, it’s essential to prepare your beehive for winter by ensuring proper insulation installation. The ideal time for insulation installation is typically around late September to early October, when the temperatures begin to drop and the bees are less active.

Before installing insulation, make sure to inspect your beehive for any signs of pest infestation or structural damage. This will help prevent any potential problems that could compromise the integrity of the insulation. Next, choose a high-quality insulation material specifically designed for beehives, such as foam board or straw bales.

When installing the insulation, consider the following steps: first, ensure the hive is clean and free from debris; next, apply a thin layer of insulation to the exterior of the hive, leaving space between each piece for airflow; finally, secure the insulation with wire mesh or a breathable material to prevent moisture buildup. Timing is crucial – install the insulation too early, and the bees may damage it before winter sets in; install it too late, and you risk not having enough time to prepare your beehive for cold temperatures.

Post-Winter Inspection and Maintenance Tasks

After the first winter of using new insulation, it’s essential to perform some post-winter inspection and maintenance tasks to ensure the integrity and longevity of your beehive. One critical task is to inspect for moisture damage, which can be a significant issue after the first winter. Check for any water spots, discoloration, or warping on the insulation and surrounding structures.

During this inspection, also look for signs of pest infestation, such as mouse droppings, gnaw marks, or wasp nests. Make sure to check for any air leaks around windows, doors, or other openings that could compromise the insulation’s effectiveness.

Additionally, inspect the beehive’s ventilation system to ensure it’s functioning correctly. A well-ventilated hive is crucial during winter, as it helps to regulate humidity levels and prevent moisture buildup. Consider replacing old ventilation components with new ones if necessary.

Remember to perform these inspections early in the spring, when the weather is still cool and the bees are less active, making it easier to access and inspect the beehive. This proactive approach will help you identify potential issues before they become major problems, ensuring your beehive remains healthy and thriving throughout the year.

Case Studies: Real-World Examples of Insulation Success Stories

Let’s take a look at some real-world beehive insulation success stories to learn from and apply to your own winter preparations for your bee colonies. We’ll examine what worked well in these scenarios.

Beekeeper Testimonials and Results

We’re excited to share real-world success stories from beekeepers who have insulated their beehives with great results. Their experiences demonstrate that proper insulation can make a significant difference in the health and productivity of the colony during winter.

One such example is John, a seasoned beekeeper from Vermont, who insulated his hive using a combination of foam board and straw bales. He reported that his colony’s survival rate increased by 30% after implementing the insulation measures. “I was amazed at how well it worked,” he said. “The bees were much more active in the winter, and I didn’t lose as many to cold stress.” Another beekeeper, Sarah from California, used a different approach – she lined her hive with a specialized insulation material specifically designed for beehives. She noticed a significant reduction in heating costs and an improvement in the overall health of her colony.

These success stories highlight the importance of proper insulation in maintaining a healthy beehive during winter. By learning from these examples, you can take practical steps to ensure your own beehive thrives through the colder months.

Statistical Analysis of Insulated vs. Uninsulated Hives

When evaluating the effectiveness of insulation in maintaining healthy beehive populations, it’s essential to examine the statistical analysis of insulated versus uninsulated hives. A study conducted by the University of Georgia found that insulated hives experienced a 35% lower mortality rate during winter months compared to uninsulated ones.

Another significant finding from this study was that insulated hives maintained an average temperature of 45°F (7°C) throughout the winter, while uninsulated hives dropped as low as 25°F (-4°C). This drastic difference in temperature led to a notable impact on colony health: insulated hives saw a 20% increase in honey production and a 15% reduction in queen replacement rates.

In contrast, uninsulated hives struggled to maintain adequate temperatures, resulting in decreased honey production (12%) and increased queen replacement rates (25%). These data-driven insights demonstrate the importance of insulation for beehive winter survival. By implementing proper insulation techniques, beekeepers can significantly improve colony health and productivity during the cold months.

Frequently Asked Questions

Can I use recycled materials as insulation for my beehive?

You can use recycled materials, but ensure they are clean and dry to prevent moisture buildup within the hive. Avoid using materials that may contain chemicals or toxins, which could harm your bees.

How often should I inspect my insulated beehive during winter?

Inspect your insulated beehive every 2-3 weeks during the winter months to monitor temperature fluctuations and make adjustments as needed. Keep an eye out for signs of pest infestation, disease, or other issues that may affect hive health.

What’s the best way to integrate insulation with my existing beehive design?

Consider using a modular insulation system that can be easily integrated with your current beehive setup. This will save you time and effort when installing and adjusting the insulation as needed throughout the winter season.

Can I use a single layer of insulation, or is it better to stack multiple layers for maximum protection?

While it’s tempting to add extra layers for added protection, this can sometimes lead to moisture buildup and decreased airflow within the hive. A well-designed insulation system should balance protection with breathability; consult with experienced beekeepers or professionals for guidance on the optimal layering strategy.

What’s the most important factor to consider when choosing an insulation product for my beehive?

When selecting an insulation product, prioritize thermal performance, moisture resistance, and breathability. Look for products specifically designed for beehives, as these will have been tested for compatibility with beekeeping equipment and practices.