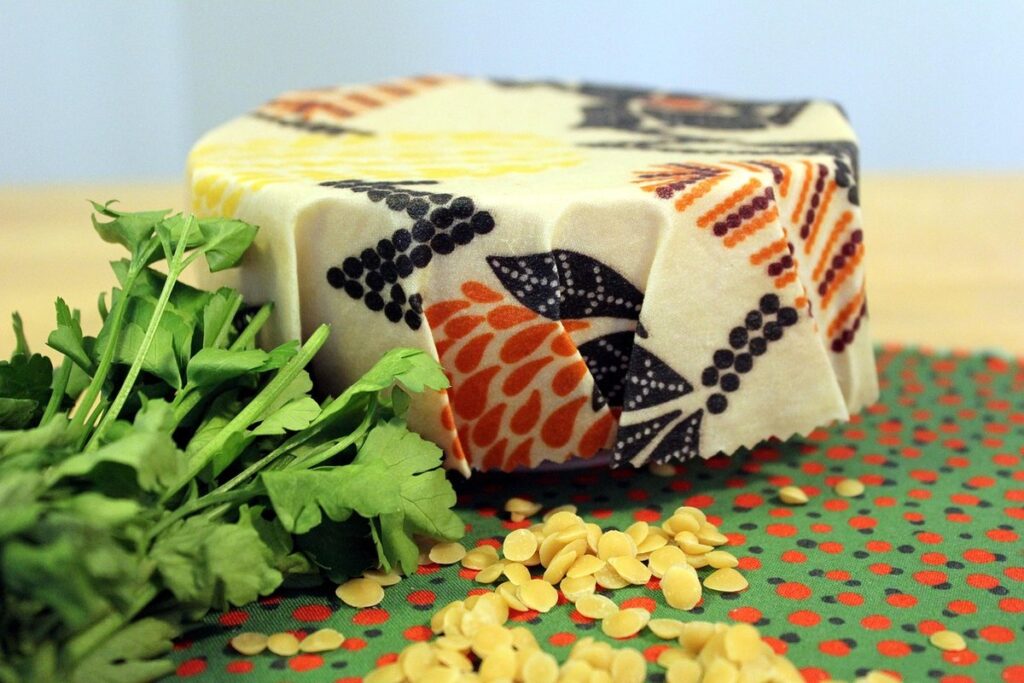

The joy of using reusable beeswax wraps, but then they start to lose their sticky charm. Don’t worry, we’ve all been there! Rewaxing your beeswax wraps is an easy way to breathe new life into them and extend their lifespan. By learning how to rewax your wraps, you can save money by avoiding frequent replacements, reduce waste, and keep using the eco-friendly products you love.

In this step-by-step guide, we’ll walk you through the process of rewaxing your beeswax wraps safely and effectively. You’ll discover how to prepare the right materials, melt wax without any mishaps, and apply a new coating that will leave your wraps looking and performing like new again. With these secrets up your sleeve, you’ll be able to enjoy your reusable wraps for even longer and make them a staple in your sustainable kitchen routine.

Preparing Your Beeswax Wraps for Rewaxing

Before you dive into rewaxing your beeswax wraps, it’s essential to prepare them properly to ensure a smooth and successful process. Remove any residue from food and wash your wraps thoroughly in warm soapy water.

Checking the Condition of Your Wraps

Before you start rewaxing your beeswax wraps, it’s essential to check their condition and determine if they need a new layer of wax. Look for signs of wear and tear, such as cracks, brittleness, or a loss of flexibility. If your wraps are showing any of these symptoms, it may be time to give them a rewax.

Check the color and texture of your wraps – if they’re looking dull or discolored, it could be a sign that the wax has broken down. You can also run a test by folding your wrap in half several times; if it cracks easily or tears, it’s likely due for a new coat of wax.

Other signs that your beeswax wraps may need rewaxing include wrinkles, creases, or scratches on the surface. If you notice any of these issues, it’s best to rewax your wraps before they become more severe problems.

Cleaning and Drying Your Wraps

Before rewaxing your beeswax wraps, it’s essential to clean and dry them thoroughly. This may seem like a straightforward task, but improper cleaning can lead to water spots, affect the wraps’ texture, and even compromise their ability to rewax evenly.

Start by gently wiping down each wrap with a soft cloth or sponge, removing any visible debris, dust, or food residue. Avoid using harsh chemicals or abrasive cleaners, as these can strip away the wax coating and damage the fabric. For tougher stains, mix 1 tablespoon of white vinegar with 2 cups of warm water to create a gentle cleaning solution. Dip a clean cloth into the solution, wring it out thoroughly, and wipe down the affected area.

To prevent water spots from forming, ensure your wraps are completely dry before rewaxing them. You can speed up the drying process by laying them flat on a wire rack or by placing them in a well-ventilated area. Never put your beeswax wraps in the oven to dry, as this can melt the wax and cause it to become unevenly distributed during the rewaxing process.

By properly cleaning and drying your beeswax wraps, you’ll be able to achieve an even, professional-looking finish when you reapply the wax coating.

Gathering Materials for Rewaxing

To rewax your beeswax wraps successfully, you’ll need to gather a few essential materials that will help you achieve professional-looking results at home. Be sure to stock up on these supplies before you begin.

Choosing the Right Beeswax

When it comes to rewaxing beeswax wraps, choosing the right type of beeswax is crucial for achieving a durable and long-lasting finish. There are several types of beeswax available on the market, each with its own unique characteristics.

For rewaxing purposes, you’ll want to opt for high-quality beeswax that’s specifically designed for candle-making or cosmetic applications. This type of beeswax will typically be labeled as “high-melt” or “pure beeswax.” Look for a product that contains at least 95% pure beeswax and minimal additives.

Color can also play a role in your decision, but it’s not the most critical factor. Some beeswaxes may have a slight yellow or brown tint due to natural impurities, but this shouldn’t affect the performance of your wraps. Be wary of very cheap beeswax that may contain fillers or artificial dyes.

When selecting a beeswax for rewaxing, also consider your budget. While high-end beeswax can be more expensive, it’s often worth the investment for its superior quality and durability. A good rule of thumb is to spend at least $10-$15 per pound of beeswax to ensure you’re getting a product that will provide long-lasting results.

Selecting a Melting Pot and Thermometer

When it comes to rewaxing beeswax wraps, selecting the right equipment is crucial for achieving professional results and ensuring a safe working environment. A melting pot specifically designed for wax re-melting is essential for this process. This type of pot should be made from heat-resistant materials such as stainless steel or ceramic, with a wide mouth to allow for easy pouring.

A thermometer is another critical piece of equipment you’ll need to accurately monitor the temperature of your melted wax. Most waxes melt between 180°F and 190°F (82°C to 88°C), but it’s crucial to stay within this range to prevent overheating, which can cause the formation of toxic fumes or even start a fire.

When choosing a thermometer, look for one that is specifically designed for high-temperature applications. A digital thermometer will give you quick and accurate readings, allowing you to make adjustments as needed. Always place the thermometer in the melted wax, not near it, to ensure accurate temperature measurements.

Rewaxing Your Beeswax Wraps: The Process

Now that you’ve had your beeswax wraps for a while, it’s likely they need a refresh to keep them in great condition and maintain their non-stick properties. Let’s go through the simple rewaxing process together!

Heating and Melted Wax Preparation

When it’s time to rewax your beeswax wraps, melting the wax is a crucial step that requires attention to detail. To prevent overheating and ensure consistent temperature control, we recommend using a double boiler setup. This involves placing the beeswax in a heat-proof glass bowl set over a pot of simmering water. As the wax melts, it’s essential to monitor its temperature, aiming for a range between 180°F and 190°F (82°C to 88°C).

To ensure even heating, you can also add a thermometer to your double boiler setup. This will allow you to maintain a consistent temperature, which is vital for achieving a smooth, even finish on your wraps. If the wax gets too hot, it can become discolored or develop an unpleasant odor.

As a general rule of thumb, it’s best to heat the wax in small increments, stirring occasionally to prevent scorching. By being mindful of temperature control and using the right equipment, you’ll be well on your way to successfully rewaxing your beeswax wraps.

Applying the New Wax Coating

Now that you’ve cleaned and dried your beeswax wraps, it’s time to apply a new layer of melted wax. This is an essential step to maintain the effectiveness and durability of your wraps. To achieve even coverage, start by pouring a small amount of melted wax onto one wrap at a time. Use a brush or spatula to spread the wax evenly across the surface, making sure to cover all areas thoroughly.

As you apply the wax, pay attention to the temperature of the liquid. If it’s too hot, it can seep through the fibers and create an uneven finish. On the other hand, if it’s too cold, it won’t adhere properly. Ideally, aim for a temperature between 180°F to 190°F (82°C to 88°C). To avoid drips or spills, work in small sections and use a steady hand when pouring the wax.

Remember to apply a thin layer of wax, as excess coating can lead to a sticky finish. It’s better to err on the side of caution and apply multiple thin layers rather than one thick layer that may compromise the integrity of your wraps.

Cooling and Curing Your Rewaxed Wraps

Now that you’ve rewaxed your wraps, it’s essential to let them cool and cure properly before using them again. This process ensures they’re ready for their next use and performs well.

Setting Up a Safe Environment for Cooling

Before you can start cooling your rewaxed wraps, it’s essential to set up a safe environment for this process. This is crucial because overheating or uneven cooling can cause the wax to melt, creating a mess and potentially damaging the wraps.

To create an ideal environment, ensure good ventilation in the area where you’ll be cooling the wraps. Open windows or use a fan to circulate the air, as stagnant air can lead to condensation that might compromise the quality of your rewaxed wraps. Next, prepare the surface on which you’ll place the wraps for cooling. A smooth, heat-resistant surface such as a ceramic tile, silicone mat, or metal tray is ideal.

Avoid using surfaces like wood, cardboard, or paper products as they can absorb moisture from the wax and damage them. If you’re working with a large quantity of wraps, consider investing in a silicone cooling rack that’s specifically designed for this purpose. This will not only save you space but also ensure even cooling and prevent any potential hotspots.

When arranging your cooling area, make sure to leave enough space between each wrap to allow for air circulation. This is especially important if you’re working with a large batch of wraps.

Monitoring the Curing Process

As you wait for your rewaxed wraps to cure, it’s essential to know what to expect and when they’ll be ready for use again. The curing process typically takes anywhere from 24 to 48 hours, depending on factors like temperature and humidity.

During this time, keep an eye out for a few key signs that indicate your wraps are ready. Firstly, check the texture – once cured, the wax should feel smooth and pliable, similar to before rewaxing. You can also test the wraps’ adhesion by applying them to a clean surface; if they stick well, it’s a good sign.

Another crucial factor is the color of the wax. When initially applied, the new layer may appear shiny or uneven. However, as the wax cures and oxidizes, it should gradually darken and even out, taking on its characteristic matte finish. If you notice any unusual odors or textures during this process, don’t hesitate to give your wraps a little extra time.

Keep in mind that patience is key here – it’s tempting to rush back into using your rewaxed wraps as soon as possible, but premature use can compromise their effectiveness and lead to a shorter lifespan.

Frequently Asked Questions

How Long Does a Rewaxed Beeswax Wrap Typically Last?

A rewaxed beeswax wrap can last for several months, depending on how well you care for it and how often you use it. With proper maintenance, including washing by hand in warm soapy water and avoiding the microwave or dishwasher, your wraps can remain effective for at least 6-12 months. Regularly checking their condition and rewaxing them as needed will help extend their lifespan.

What If My Beeswax Wraps Are Too Brittle to Rewax?

If your beeswax wraps are too brittle to rewax, it may be a sign that they have reached the end of their life cycle. In this case, consider replacing them with new ones. However, if you want to try and salvage them, gently heat them up in a gentle oven (150°F – 200°F) for about an hour before attempting to rewax them. Be cautious not to overheat or melt the wraps.

Can I Rewax My Beeswax Wraps More Than Once?

Yes, beeswax wraps can be rewaxed multiple times, but it’s essential to do so carefully and follow proper techniques to ensure the wax adheres evenly and doesn’t compromise the wrap’s structure. Avoid over-rewaxing as this may lead to a thick, sticky layer that becomes difficult to clean.

How Do I Store Rewaxed Beeswax Wraps?

To keep your rewaxed beeswax wraps in good condition, store them away from direct sunlight, heat sources, and moisture. Fold or roll the wraps neatly and place them in an airtight container or bag, like a ziplock or cloth pouch. This will help maintain their flexibility and prevent them from drying out.

Can I Use Different Types of Wax for Rewaxing My Beeswax Wraps?

While you can use different types of wax for rewaxing your beeswax wraps, it’s recommended to stick with 100% natural beeswax. Other waxes, such as soy or carnauba, may affect the performance and longevity of your wraps. If you choose to experiment with alternative waxes, be sure to test a small area first to ensure compatibility and desired results.