Protecting your bee colony from extreme temperatures and moisture issues is crucial for their health and productivity. Harsh weather conditions can be detrimental to the hive, causing stress on the bees and potentially even leading to colony loss. To ensure a thriving colony, it’s essential to consider insulating your beehive. But what are the best insulation materials – natural or synthetic? And how do you choose between DIY techniques and commercial solutions? In this article, we’ll delve into the world of beehive insulation, exploring expert advice on selecting the right materials for your needs. We’ll also provide practical tips on installing insulation effectively and maintaining a healthy, insulated hive throughout the seasons. Whether you’re a seasoned beekeeper or just starting out, our guide will help you keep your colony safe and thriving all year round.

The Importance of Beehive Insulation

Proper beehive insulation is crucial for keeping your bees healthy and happy, which is why we’re diving into the importance of adequate ventilation and insulation in this section.

Reducing Heat Loss in Cold Climates

When you live in an area with cold winters, maintaining a stable temperature within your beehive is crucial for your bee colony’s survival. Cold temperatures can have devastating effects on the health and productivity of your bees. A prolonged exposure to chilly conditions can cause their metabolism to slow down, making them more susceptible to disease and pests.

Inadequate insulation in cold climates can lead to a significant decrease in honey production, which is often the primary goal for beekeepers. Without proper insulation, heat loss from the hive can be substantial, causing the temperature inside to drop by as much as 10-15°F (5-8°C) within hours of exposure to cold air.

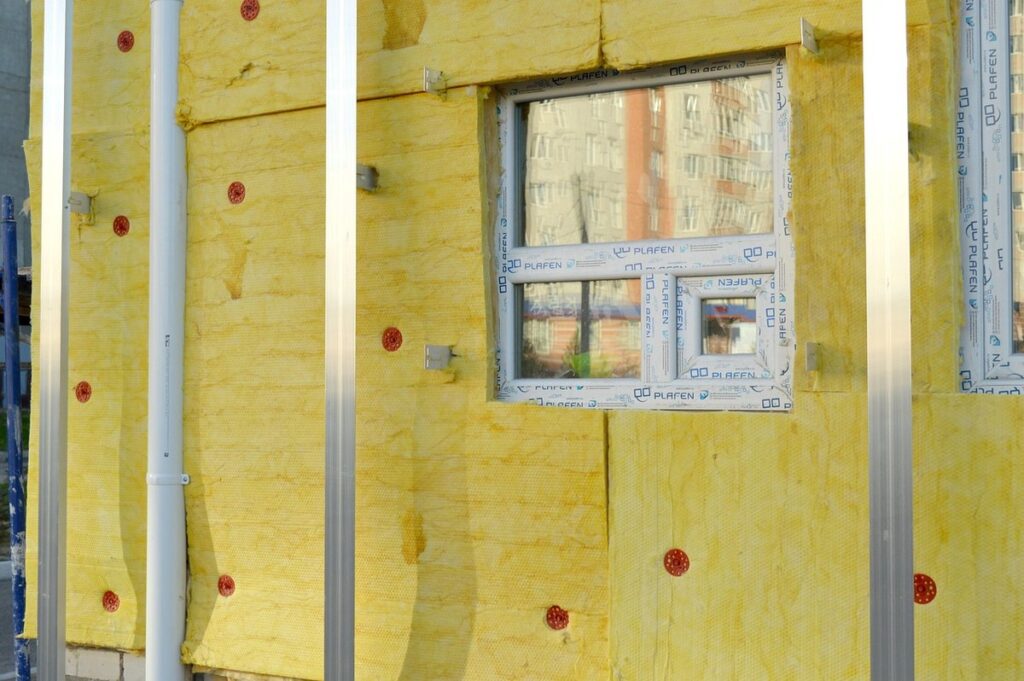

To combat this issue, you should ensure that your beehive has sufficient insulation. This means installing a robust outer shell or wrapping the hive with insulating materials such as foam board, straw, or even shredded newspaper. Additionally, keeping the hive in a location protected from harsh winds and extreme temperature fluctuations can also help minimize heat loss.

A well-insulated beehive is not only essential for maintaining a stable temperature but also helps to reduce stress on your bees, promoting a healthier and more productive colony overall.

Managing Moisture and Condensation Issues

Managing moisture and condensation issues is crucial when it comes to beehive insulation. Excessive humidity can lead to mold growth on the hive’s interior surfaces, creating an unhealthy environment for your bees. This can cause a range of problems, from reduced honey production to increased susceptibility to diseases.

Proper ventilation plays a significant role in preventing these issues. Ensure that your beehive is situated with adequate airflow, either by installing a screened bottom or using a ventilation system specifically designed for beehives. Regularly inspecting the hive’s interior and exterior can help you identify any condensation problems early on.

In addition to proper ventilation, choosing the right insulation material can also make a significant difference. A good quality insulation like foam board or straw bales will help regulate temperature fluctuations and reduce moisture accumulation within the hive.

Types of Beehive Insulation Materials

When it comes to insulating your beehive, you have several options to choose from, each with its own unique benefits and drawbacks. Let’s dive into the most common types of insulation materials used in beekeeping.

Natural Insulation Options (Straw, Hay, Etc.)

When it comes to natural insulation options for your beehive, straw and hay are popular choices among beekeepers. These materials have been used for centuries to keep bees cozy and warm during the cold winter months.

Straw is a good option for its lightweight and breathable properties, making it easy to install and remove as needed. However, it can be prone to moisture issues if not properly sealed, which can lead to mold growth and damage to the hive. To minimize this risk, make sure to choose straw that’s dry and free of any debris.

Hay, on the other hand, is a more dense material that provides better insulation against extreme temperatures. It’s also less prone to moisture issues than straw, but it can be heavier and more difficult to install. When using hay for insulation, consider layering it with other materials like foam or wood chips to ensure adequate ventilation.

Ultimately, the choice between straw and hay comes down to your specific climate and preferences. If you live in a milder region, straw might be a good option. But if you’re in an area with harsh winters or extreme temperatures, hay may provide better protection for your bees.

Synthetic Insulation Materials (Foam, Plastic, Etc.)

When it comes to beehive insulation materials, synthetic options like foam and plastic have gained popularity in recent years. These materials offer several advantages over natural ones, making them an attractive choice for beekeepers.

One of the primary benefits of synthetic insulation is its durability. Unlike natural materials that can break down or deteriorate over time, foam and plastic retain their insulating properties even after prolonged exposure to moisture and temperature fluctuations. This means you won’t have to worry about replacing your insulation as frequently, saving you time and money in the long run.

Additionally, synthetic insulation is relatively easy to install, especially when compared to natural materials like wool or straw. Most foam and plastic insulation products come pre-cut and ready for use, making it simple to get started right away. For example, you can easily wrap foam sheets around your beehive frames or attach plastic panels to the exterior.

Some popular synthetic insulation options include:

* Extruded polystyrene foam (XPS) for its high R-value and moisture resistance

* Polyisocyanurate (PIR) foam for its excellent thermal performance and durability

* Plastic film wraps, such as polyethylene or polypropylene, for their ease of use and affordability

When selecting synthetic insulation materials, be sure to consider factors like R-value, moisture resistance, and ease of installation. With a little research and planning, you can find the perfect synthetic insulation solution for your beehive needs.

DIY Beehive Insulation Techniques

To keep your bees warm and cozy, you’ll need some effective insulation techniques that don’t break the bank or compromise their safety. Here are our top DIY beehive insulation tips.

Building a Straw-Bale Hive

Building a straw-bale hive requires careful planning and execution to ensure it provides adequate insulation while maintaining good ventilation and structural integrity. Begin by selecting high-quality straw bales that are free from debris and moisture. You’ll need approximately 3-4 bales per square foot of hive space, depending on the desired level of insulation.

To build your straw-bale hive, start by creating a wooden frame to serve as the base. Place the straw bales within the frame, leaving about an inch of space between each layer for ventilation. Use a mixture of soil and sand to hold the bales in place, ensuring they are securely fastened to the frame.

For moisture control, consider adding a waterproof membrane between the straw bale layers. This will prevent moisture from accumulating and causing mold or rot. Additionally, ensure good airflow by installing vents at regular intervals within the hive. By following these steps, you can create an effective straw-bale hive that provides excellent insulation while maintaining a healthy environment for your bees.

When building your straw-bale hive, consider the local climate and adjust your design accordingly. For example, in colder regions, add extra insulation by using more bales or incorporating additional materials like recycled denim. With proper construction and maintenance, a straw-bale hive can be a cost-effective and eco-friendly solution for beekeepers worldwide.

Creating a Foam-Based Insulated Hive

Creating an insulated beehive using foam-based materials can provide excellent temperature control and protection for your bees. However, it’s essential to note that many foam products emit volatile organic compounds (VOCs), which can be hazardous to both humans and bees.

To mitigate this risk, opt for foam insulation with low or no VOC emissions. Some popular alternatives include eco-friendly foam boards made from recycled materials or natural fibers like cotton and wool. When selecting a product, always check the manufacturer’s data sheet for emission levels and consider using protective gear when handling the material.

When constructing your insulated hive, ensure proper ventilation to prevent moisture buildup and minimize the impact of VOCs on your bees. This can be achieved by installing vents or gaps in the insulation that allow for airflow while maintaining temperature control. It’s also crucial to choose a foam product that is not too dense, as this can hinder airflow within the hive.

Some beekeepers have successfully used foam-based insulation with careful planning and precautions. For instance, using expanded polystyrene (EPS) foam boards in combination with natural ventilation has been shown to maintain temperatures within 1-2°C of the outside temperature without compromising air quality inside the hive.

Commercial Beehive Insulation Solutions

When it comes to keeping your commercial beehives insulated and healthy, you need solutions that are specifically designed for large-scale operations. This section will explore some effective options for insulating your beehives.

Professional Installation Services

When it comes to commercial beehive insulation solutions, hiring professional installation services is a crucial decision that can make all the difference in ensuring the longevity and efficiency of your insulated beehives. One of the primary benefits of hiring professionals is that they bring with them extensive knowledge and experience in installing insulation materials specifically designed for beehives.

Proper installation by trained technicians ensures that insulation materials are applied correctly, preventing any potential damage to the hive or its occupants. Moreover, professional installers only use high-quality insulation materials, such as spray foam or fiberglass, which provide optimal thermal performance and protection against pests and diseases. Additionally, reputable companies often offer comprehensive after-sales support, including warranty coverage and maintenance advice.

Some key factors to consider when selecting a professional installation service include their reputation, certifications, and equipment quality. Reputable installers will also conduct thorough site assessments to ensure that the insulation solution meets specific requirements of your beehive operation. By investing in professional installation services, you can rest assured that your commercial beehives are properly insulated, reducing energy costs and optimizing overall operational efficiency.

DIY Kits and Components

For beekeepers on a budget or with limited DIY experience, pre-made kits and components are an attractive option for commercial beehive insulation. These self-installation products cater to various hive sizes and types, offering a range of materials, from foam board to straw-based solutions.

Pros of using pre-made kits include cost-effectiveness, reduced labor time, and straightforward installation processes. Many manufacturers provide detailed instructions and online resources to ensure successful assembly. Additionally, these kits often utilize high-quality insulation materials that meet industry standards.

However, some drawbacks exist: limited customization options and potential compatibility issues with existing hive components can be concerns. Furthermore, while pre-made kits save on labor costs, they may not address specific hive performance problems as effectively as professional installation services.

Before selecting a DIY kit or component, consider your beekeeping expertise, available space for assembly, and the specific insulation needs of your commercial operation. Researching manufacturer recommendations, reading reviews from other users, and consulting with experienced beekeepers can help you make an informed decision that balances convenience with effectiveness.

Maintenance and Upkeep Considerations

To ensure a long-lasting beehive, it’s essential to regularly inspect and maintain your insulation system. Regular checks will prevent damage and maintain optimal temperature conditions for your bees.

Monitoring Temperature and Humidity Levels

Monitoring temperature and humidity levels within your beehive is crucial for maintaining a healthy colony. Without proper monitoring, you may not realize that conditions are becoming too hot, cold, or humid, which can stress the bees and impact their growth.

You can use specialized instruments like thermometers and hygrometers to measure temperature and humidity levels in the hive. These devices usually come with a digital display that shows readings in real-time. You can place them inside the hive near the brood nest or on top of the hive body, depending on your setup. Regularly check these readings to ensure they stay within optimal ranges.

A general guideline for temperature is between 92°F and 95°F (33°C-35°C) during summer months, while humidity levels should remain around 60% to 70%. Keep in mind that temperature fluctuations can be more critical than absolute temperature values. For example, a sudden drop in temperature at night can shock the colony.

By tracking these parameters, you’ll gain insights into the hive’s thermal and humid conditions, allowing you to make informed decisions about insulation adjustments or other maintenance tasks.

Regular Inspections and Repairs

Regular inspections and repairs are crucial to maintaining the effectiveness of beehive insulation. As you monitor the system over time, keep an eye out for signs of wear, such as gaps between panels, damaged components, or excessive dust accumulation.

Schedule a thorough inspection at least once every 6-12 months, ideally during periods of high usage or after extreme weather events. Begin by checking for any visible damage to the insulation material itself, including tears, holes, or discoloration. Next, inspect the beehive’s structural integrity, ensuring that it remains securely fastened to the foundation.

When conducting your inspection, also take note of how the insulation is performing in different environmental conditions. Check if it’s still providing adequate temperature regulation and moisture control. If you notice any issues, address them promptly to prevent further damage or compromised performance. Replace any damaged components immediately, following the manufacturer’s instructions for replacement.

Conclusion

Now that you’ve learned about the importance of beehive insulation, it’s time to put this knowledge into action. Remember, proper insulation is crucial for your bees’ survival and productivity throughout the seasons. To recap, consider the types of insulation we discussed – from foam board to straw bales, each with its own benefits and drawbacks. Think about your local climate and what will work best for your specific beehives. If you’re just starting out, it may be helpful to start small and experiment with different materials before investing in a larger-scale solution.

By taking these steps, you can help ensure the health and happiness of your bees, as well as enjoy a successful beekeeping experience. Don’t forget to also consider regular maintenance and inspections to keep your insulation in top condition. With a little practice and patience, you’ll be on your way to becoming a seasoned beekeeper with thriving colonies.

Frequently Asked Questions

Can I use a combination of natural and synthetic insulation materials for my beehive?

Yes, many beekeepers successfully combine different insulation types to achieve optimal results. For example, you might use straw or hay as a natural insulator on the exterior and foam board as a synthetic liner within the hive. Just ensure that any materials used are non-toxic and won’t harm your bees.

How do I know if my beehive is experiencing moisture issues, and what can I do to fix them?

Monitor temperature and humidity levels regularly using a thermometer and hygrometer. If you notice condensation or excessive moisture inside the hive, consider upgrading to a more breathable insulation material like straw bales or installing a ventilation system to improve airflow.

Can I install beehive insulation myself without professional help, or is it recommended to hire an expert?

While DIY insulation techniques can be cost-effective and efficient, complex projects like building a straw-bale hive may require professional assistance. Consider your level of expertise and the specific needs of your colony before deciding whether to take on the task yourself.

What are some common mistakes beekeepers make when insulating their hives, and how can I avoid them?

Some common pitfalls include inadequate ventilation, which can lead to moisture buildup; using low-quality insulation materials that may harbor pests or mold; and neglecting regular inspections and maintenance. Regularly inspect your hive for signs of damage or wear, and stay up-to-date with best practices in beehive insulation.

How often should I replace or repair the insulation in my beehive to ensure optimal performance?

The frequency of replacement depends on various factors, including climate, usage, and type of insulation. As a general rule, inspect your hive regularly (at least quarterly) for signs of wear and damage. Replace any damaged or ineffective insulation promptly to maintain a healthy, productive colony.