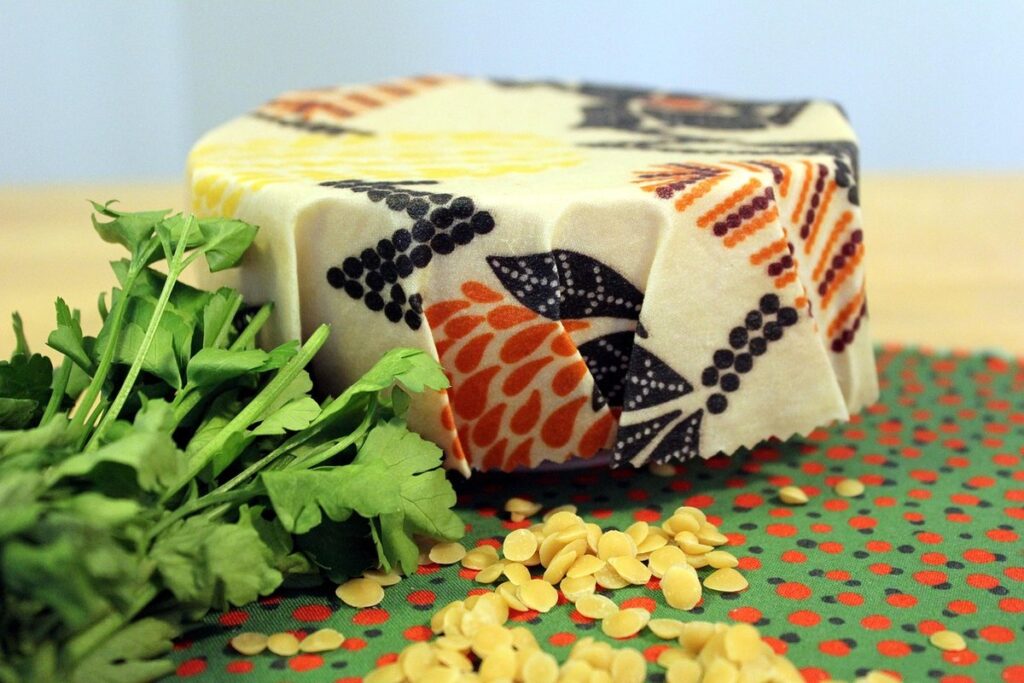

Are you tired of using plastic wrap for food storage, but don’t know where to start with more eco-friendly alternatives? Making your own beeswax wraps without resin is a game-changer. Not only can it help reduce waste and save you money in the long run, but it also allows you to customize your wraps to fit your specific needs. Gone are the days of limited size options and harsh chemicals found in many commercial products.

In this article, we’ll walk you through the simple process of creating your own beeswax wraps using natural ingredients like cotton, beeswax, and jojoba oil. We’ll cover everything from choosing the right materials to tips for achieving a smooth, even finish. By the end of it, you’ll be equipped with the knowledge to create your own reusable and sustainable beeswax wraps without resin, taking a big step towards a more environmentally friendly lifestyle.

The Benefits of Homemade Beeswax Wraps

Making your own beeswax wraps without resin is not only cost-effective but also allows you to control the ingredients and customize the products to meet your specific needs.

Reducing Waste and Saving Money

When you make your own beeswax wraps at home, you not only avoid using resin but also significantly reduce waste and save money on store-bought alternatives. Let’s break down the numbers: a single pack of commercial beeswax wraps can cost anywhere from $10 to $20, depending on their size and quality.

By contrast, making your own beeswax wraps requires just a few simple ingredients – including pure beeswax, jojoba oil, and cotton fabric. A standard roll of cotton cloth can be repurposed multiple times when coated with the homemade beeswax mixture, essentially turning one $5 cloth into dozens of reusable wraps.

This DIY approach also eliminates packaging waste associated with commercial products. Store-bought wraps often come in plastic bags or boxes, which contribute to a staggering 30% of household waste. By choosing to make your own beeswax wraps, you’re not only saving money but also reducing your environmental footprint.

Customization Options

One of the best things about making your own beeswax wraps is that you can customize them to fit your specific needs and preferences. This means you can tailor the size, shape, and even color of your wraps to suit your lifestyle and taste.

When it comes to customizing your beeswax wraps, there are a few key areas to consider. First, think about the size of your wraps. Do you need large ones for wrapping big bowls or small ones for covering snacks? You can easily make multiple sizes at once by adjusting the amount of fabric you use. For example, if you’re making a batch of wraps, you can cut out four large squares and two smaller ones from the same piece of cloth.

Another way to customize your beeswax wraps is by adding different textures or colors. This can be achieved by using various fabrics, such as cotton, linen, or even hemp, which all have unique properties that affect how they absorb and release moisture. You can also add natural dyes like turmeric, indigo, or pomegranate juice to create a range of colors.

In addition to these basic customizations, you can also experiment with different ratios of beeswax to jojoba oil to achieve the perfect balance for your needs. For example, if you live in a very humid climate, you may want to use more beeswax to help prevent mold growth.

Choosing the Right Ingredients

When it comes to making beeswax wraps without resin, selecting the right ingredients is crucial for a successful and reusable wrap. We’ll guide you through choosing the perfect blend of natural oils and waxes.

Selecting High-Quality Beeswax

When it comes to making high-quality beeswax wraps without resin, selecting the right type of beeswax is crucial. Not all beeswax is created equal, and using low-quality wax can result in fragile, ineffective wraps that may not perform as well as you need them to.

To ensure your wraps are durable and long-lasting, look for pure beeswax that contains no additives or fillers. Pure beeswax has a high melting point, which means it will maintain its shape and structure even at high temperatures, making it ideal for wrapping food and storing items in the pantry.

When shopping for beeswax, check the label for the following: a high percentage of pure beeswax (typically 99% or higher), no additives or chemicals, and a clear indication of where the wax is sourced from. Some manufacturers may also indicate the type of flowers used to produce the honey that makes up the wax.

By choosing high-quality beeswax, you’ll be able to create wraps that will withstand repeated use and cleaning, and provide effective protection for your food and belongings.

Adding Natural Oils for Conditioning

When it comes to making your own beeswax wraps without resin, incorporating natural oils is a great way to enhance their performance and extend their lifespan. Natural oils not only condition the beeswax but also provide additional benefits such as flexibility, durability, and antimicrobial properties.

Some popular natural oils you can use for conditioning include jojoba oil, coconut oil, olive oil, and avocado oil. Jojoba oil is an excellent choice because it has a similar composition to human skin’s natural oils, making it easily absorbed and gentle on surfaces. Coconut oil adds a high level of antimicrobial protection, which helps prevent the growth of bacteria and mold.

When choosing an oil for your beeswax wraps, consider their melting points and viscosities. For example, olive oil has a relatively low melting point, so it’s best used in combination with other oils to achieve the right balance. Avocado oil is another good option due to its high smoke point, making it perfect for wrapping hot foods.

Experiment with different ratios of natural oils to beeswax to find the perfect blend that works for you. Typically, a 10-20% oil content is sufficient, but this may vary depending on your personal preference and needs.

Preparing Your Workspace

Before we dive into making our beeswax wraps, let’s set up a clean and organized workspace to ensure our project goes smoothly and safely. Gather your materials and prep your space accordingly.

Setting Up a Clean and Well-Ventilated Area

When working with beeswax and other materials to create your wraps, it’s essential to set up a clean and well-ventilated workspace to ensure safe and successful wrapping. Start by clearing the area of any clutter or distractions, and lay down a protective surface such as a plastic tablecloth or old sheets to make cleanup easier.

Good ventilation is crucial when working with wax and heat. Open windows and use a fan to circulate the air, or invest in a good quality extraction system if you’re planning on making wraps regularly. You’ll also want to have a dust mask handy to avoid inhaling any particles that may become airborne during the process.

Keep your workspace organized by having all your materials within easy reach, including the beeswax, cotton fabric, scissors, and iron. This will help prevent accidents and make it easier to work efficiently. Remember to wash your hands thoroughly after handling the wax and materials, and have a cleaning solution on hand to wipe down surfaces as you go along. By taking these precautions, you’ll be well-prepared for a successful wrapping experience.

Gathering Essential Tools and Supplies

To make high-quality beeswax wraps without resin, you’ll need to gather the right tools and supplies. Start by collecting a variety of cotton fabrics, preferably with a natural weave and thickness. Organic cotton is an excellent choice, as it’s breathable, durable, and eco-friendly.

You’ll also require a melting pot specifically designed for working with wax and other heat-sensitive materials. A double boiler or a dedicated wax melter will help you maintain the precise temperature needed to melt the wax without burning it. Invest in a good-quality thermometer that can accurately measure temperatures up to 180°F (82°C), as this is crucial for achieving the right melting point.

Additional essential supplies include:

• Beeswax pellets: Look for pure, high-quality wax with minimal additives.

• Jojoba oil or coconut oil: These natural oils help create a smooth, even texture and promote flexibility in your wraps.

• Optional: Essential oils or herbs for added fragrance and antimicrobial properties

• Measuring cups and spoons for accurately mixing ingredients

The Wrapping Process

Now that we’ve made our wraps, it’s time to learn how to fold and shape them perfectly for wrapping food and storing snacks. This is where technique comes in!

Melted Beeswax Preparation

To prepare the beeswax for wrapping, you’ll need to melt it down to a usable consistency. This process is crucial as it will determine the overall quality and performance of your wraps. To melt the beeswax, place it in a double boiler or a dedicated melting pot set over low heat.

Monitor the temperature carefully, aiming for a range between 180°F and 190°F (82°C to 88°C). Beeswax can be prone to overheating, which may cause discoloration or even ignition. To avoid this risk, use a thermometer to track the temperature closely. Once the beeswax reaches the desired temperature, it should be smooth and pliable.

Avoid over-melting the beeswax, as this can lead to an uneven consistency in your wraps. Instead, focus on achieving a well-balanced melt that will allow you to work with the wax effectively. Remove from heat when ready, then stir gently to prevent hot spots.

Applying a Thin Layer of Beeswax

Now that you’ve got your fabric ready and it’s time to add the beeswax layer. This is a crucial step in creating effective wraps – too little wax and they won’t seal properly, while too much can make them stiff and brittle.

Take your melted beeswax (which should be around 100-120°F or 38-49°C at this stage) and pour it evenly across the fabric, making sure to cover every inch. To ensure an even coat, use a clean brush or a silicone spatula to gently spread the wax.

Work in small sections, applying the wax thinly but thoroughly. You can start by applying the wax to one corner of your fabric and then work your way outwards, using long, smooth strokes to cover the entire area.

Pay particular attention to the seams – these are areas where moisture can seep in more easily, so make sure they’re nice and coated with wax.

Shaping and Cooling the Wrap

Now that you’ve mixed and melted the perfect blend of beeswax, jojoba oil, and natural wax, it’s time to shape and cool your wraps. This is a crucial step in achieving the desired texture and flexibility.

To begin shaping your wraps, start by pressing them out into even sheets using a parchment-lined surface or a silicone mat. Use a spatula or your hands to smooth out any wrinkles or bubbles. For larger wraps, you can use a rolling pin to roll out the mixture to an even thickness.

Next, transfer your sheet of wrap to a cooling rack set over a baking sheet lined with parchment paper. Allow the wraps to cool completely at room temperature. This is an essential step, as rushing this process can lead to uneven curing and a brittle texture.

As you wait for your wraps to cool, take note that they will shrink slightly as they dry. This is normal, so don’t worry if you find them slightly smaller than expected.

Tips and Tricks for Success

Now that you’ve mastered making beeswax wraps without resin, here are some valuable tips to help you create perfect wraps every time. You’ll learn how to troubleshoot common mistakes and achieve professional results.

Troubleshooting Common Issues

When working with beeswax wraps without resin, you may encounter some common issues that can affect their performance and durability. Uneven melting is a problem that can arise if the wax doesn’t melt consistently during the wrapping process. To avoid this, make sure to use a thermometer to monitor the temperature of your melted wax, aiming for a consistent range between 180°F and 190°F (82°C to 88°C). You can also try stirring the mixture frequently to ensure even heating.

Poor adhesion is another issue that may occur if the wraps don’t adhere properly to surfaces. This could be due to insufficient wax coating or an uneven surface. To address this, double-check your preparation of the food wrap surface by ensuring it’s clean and dry before applying the melted wax mixture. Also, make sure you’re applying a sufficient amount of wax during the wrapping process.

If you encounter either issue, try re-wrapping the item with freshly prepared wax wraps to ensure optimal performance. Regularly checking the wraps for wear and tear can also help identify any potential issues before they become major problems.

Extending the Life of Your Beeswax Wraps

To get the most out of your homemade beeswax wraps, it’s essential to extend their life by following proper storage and cleaning techniques. First, let’s talk about storage. When not in use, store your beeswax wraps in a cool, dry place away from direct sunlight. This will prevent them from becoming brittle or developing an unpleasant odor.

To clean your beeswax wraps, simply wipe them down with a soft cloth and some soap solution after each use. Avoid using abrasive materials or harsh chemicals, as these can damage the wax coating. For more stubborn stains or food residue, mix equal parts water and white vinegar in a bowl and dip a cloth into it to gently scrub the area.

Proper cleaning will help maintain the wax’s natural properties, ensuring your wraps remain effective at keeping food fresh while also being easy to clean. By following these simple storage and cleaning tips, you can enjoy using your homemade beeswax wraps for months to come.

Safety Precautions and Preparing for Production

Before you dive into making your own beeswax wraps, it’s essential to follow some important safety precautions to avoid any accidents. Please read on to learn about preparing your workspace and materials.

Handling Hot Equipment and Materials Safely

When working with hot equipment and materials to make beeswax wraps without resin, safety should be your top priority. This means being mindful of temperature control, handling techniques, and protective gear.

Beeswax can reach extremely high temperatures during the melting process, posing a risk of burns or fires if not handled properly. To minimize this risk, ensure that your workspace is clear of flammable materials and that you have a heat-resistant surface to work on. Always use oven mitts or gloves when handling hot equipment or wrapping your beeswax wraps.

It’s also crucial to monitor the temperature of your melting wax, as overheating can cause it to smoke or catch fire. Invest in a thermometer specifically designed for measuring high temperatures, and keep an eye on the temperature gauge as you melt your wax. When working with a double boiler or dedicated melting pot, never leave it unattended.

When preparing your wraps, be cautious not to splash hot wax onto yourself or nearby surfaces. Keep rags or paper towels handy to clean up any spills immediately, and work in a well-ventilated area to prevent inhaling fumes from the melting wax.

Scaling Up Your Wrapping Process

Scaling up your wrapping process can be both exciting and intimidating. As you become more confident in your recipe and technique, you’ll want to produce larger quantities of beeswax wraps for friends, family, or even a small business venture.

To start scaling up, it’s essential to consider your workspace and equipment. Ensure that you have enough space to accommodate the increased quantity of wraps without compromising on quality. You may need to invest in a new set of molds or adjust your existing ones to fit more wraps at once. For example, you could use silicone mats or multiple small molds instead of one large one.

Another critical factor is time management. Plan your production process to optimize efficiency and minimize waste. Consider the following tips:

* Prepare ingredients and materials in bulk

* Use a ‘production line’ approach, where each step is completed before moving on to the next

* Keep track of inventory levels to avoid running out of essential supplies

Remember, scaling up doesn’t have to mean sacrificing quality. With careful planning and attention to detail, you can produce high-quality beeswax wraps in larger quantities while maintaining consistency and control.

Frequently Asked Questions

How Can I Ensure My Beeswax Wraps Stay Mold-Resistant for a Long Time?

To prevent mold growth, ensure your wraps are completely dry before storing them. Store them in an airtight container or plastic bag to maintain air circulation and keep them away from moisture. You can also add a few drops of tea tree oil or lemon essential oil to the melted beeswax mixture for its natural antifungal properties.

What’s the Best Way to Clean and Reuse My Beeswax Wraps?

To clean your wraps, wipe them gently with a damp cloth and mild soap. Avoid washing in water, as it can cause the beeswax to become brittle or separate from the fabric. For tougher stains, mix equal parts water and white vinegar on the stain before wiping clean.

Can I Use Different Natural Fibers Instead of Cotton for My Beeswax Wraps?

While cotton is a popular choice due to its breathability and absorbency, you can experiment with other natural fibers like linen or hemp. Keep in mind that these fibers may require slightly different melting temperatures and ratios of beeswax to oil.

How Do I Handle the Messy Process of Working with Beeswax?

To minimize mess, work on a heat-resistant surface, such as a ceramic tile or a silicone mat. Apply a thin layer of melted beeswax to the fabric using a brush or spatula, and then use a clean cloth to wipe away excess wax. Clean your tools immediately after use.

Can I Use My Beeswax Wraps for Baking Instead of Just Food Storage?

Yes, you can use your beeswax wraps for baking, but ensure they are completely dry and free of any food residue before exposing them to high temperatures. Also, be aware that repeated exposure to heat may affect the wrap’s texture or flexibility over time.